10 Open-source and Free Manufacturing ERP and Manufacturing Management Solutions

Table of Content

Manufacturing software refers to technology solutions that help manufacturers and shelter manufacturing service providers manage various aspects of their operations, from supply chain management to inventory control to production scheduling. These solutions are designed to optimize the manufacturing process and workflow management, improve quality performance, and ultimately, increase profitability.

One of the primary benefits of manufacturing software is that it helps companies streamline their operations. By automating certain tasks and providing real-time visibility into production processes, manufacturers can reduce waste, improve efficiency, and make better decisions. This can lead to increased productivity and faster time-to-market for new products.

Manufacturing software also helps companies manage their supply chain more effectively. By providing greater visibility into the movement of raw materials and finished goods, manufacturers can optimize their inventory levels, reduce lead times, and improve their ability to respond to changes in demand.

Another advantage of manufacturing software is that it can help companies improve their quality performance. By providing greater visibility into production processes and enabling real-time monitoring of key metrics, manufacturers can identify quality issues more quickly and take corrective action before they become bigger problems.

Overall, manufacturing software is a critical tool for companies looking to optimize their operations, improve their quality performance, and increase their profitability. Whether you're a small manufacturer looking to streamline your processes or a large enterprise looking to gain greater visibility into your operations, there are a wide range of manufacturing software solutions available to help you achieve your goals.

Open-source Manufacturing Solutions

Open source software refers to software that is freely available to use, modify, and distribute. This means that companies can take advantage of manufacturing software without having to pay for expensive licenses or worry about vendor lock-in. In addition, because open source software is developed by a community of developers, it tends to be more flexible, adaptable, and customizable than proprietary software solutions.

So what are the benefits and advantages of open source manufacturing software? Here are a few key points to consider:

1- Cost Savings

Perhaps the biggest advantage of open source manufacturing software is the cost savings. By using open source software, companies can avoid the high licensing fees associated with proprietary software solutions. In addition, because open source software is developed by a community of developers, companies can take advantage of a wider range of resources and expertise without having to pay for expensive consulting services.

2- Flexibility and Customization

Open source software is known for its flexibility and customization options. Because the source code is freely available, companies can modify the software to meet their specific needs, without having to rely on a vendor for support or customization services. This means that companies can tailor the software to their unique requirements, rather than being forced to adapt their processes to fit the software.

3- Community Support

Open source software is typically developed by a community of developers who are passionate about the software and its potential. This means that companies can tap into a wide range of resources and expertise, including user forums, documentation, and support services. In addition, because the software is open source, companies can contribute their own code and improvements back to the community, helping to drive innovation and improve the software for everyone.

4- Security and Reliability

Open source software is often more secure and reliable than proprietary software solutions. Because the source code is freely available, developers can identify and fix security vulnerabilities more quickly than with proprietary software, which tends to be more closed and opaque. In addition, because open source software is developed by a community of developers, there is a greater level of accountability and transparency, which can help to improve the overall quality and reliability of the software.

In this article, we compiled a list of the best open-source and free manufacturing management solution that can save time, effort, and money for many manufacturers.

1- ERPNext

ERPNext is an open-source, cloud-based enterprise resource planning (ERP) software that helps businesses manage various aspects of their operations, from supply chain management to accounting to project management. It is designed to be flexible, customizable, and easy to use, making it a popular choice for small and medium-sized businesses.

ERPNext offers several features specifically designed for manufacturing companies.

ERPNext Key Features

- Bill of Materials (BOM) management

- Production planning and scheduling

- Work order management

- Quality control and inspection

- Inventory management

- Sales order management

- Resources management

By using ERPNext, manufacturing companies can streamline their operations, improve efficiency, and reduce waste. The software provides real-time visibility into production processes, enabling companies to make better decisions and respond more quickly to changes in demand.

ERPNext is an open-source project that is released under the GNU General Public License (v3).

2- Libre

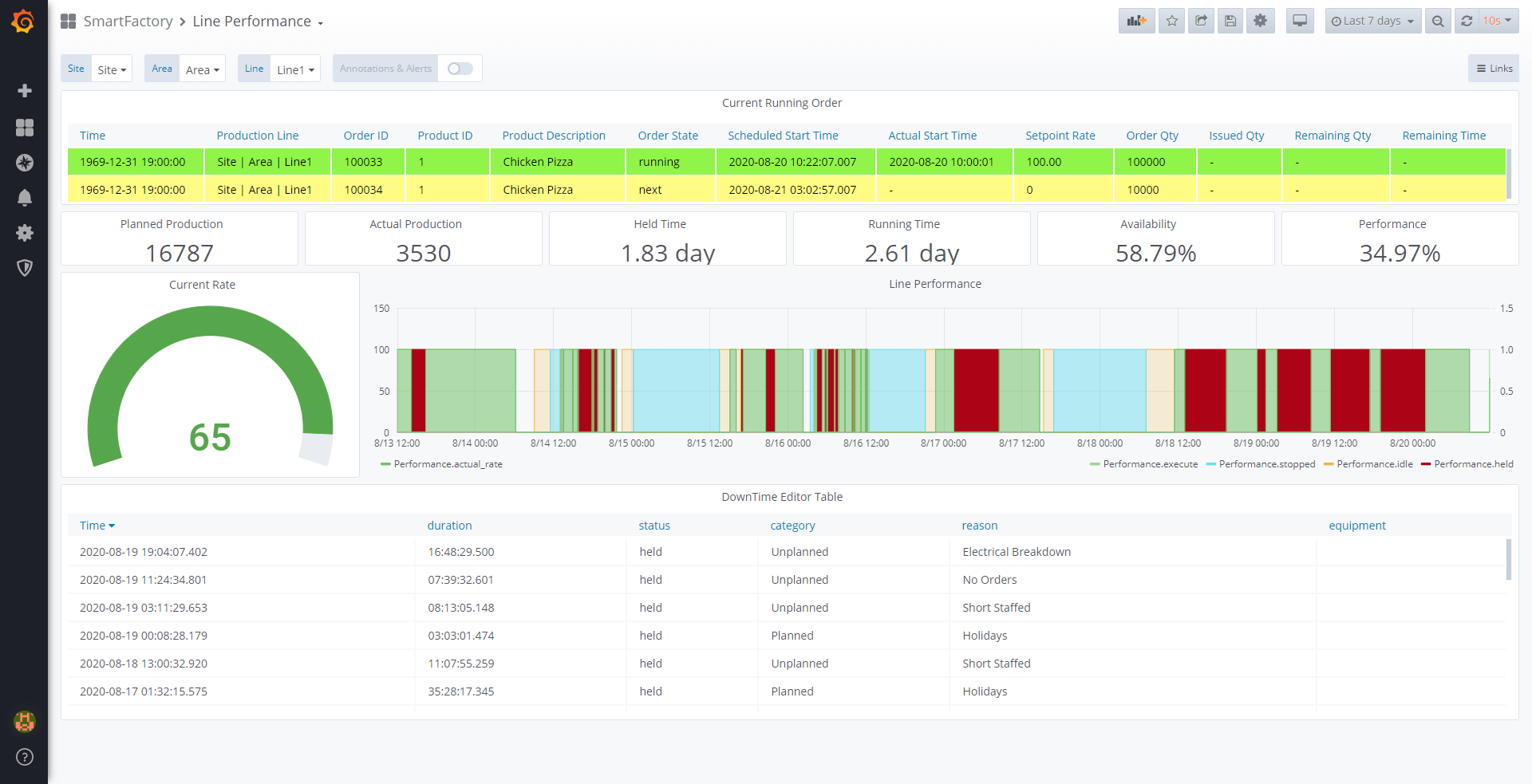

Libre is an open-source tool for monitoring manufacturing performance. It lets you define your master data, capture machine metrics, and analyze your manufacturing data to improve operations. To define your master data, create an enterprise model that includes products, ingredients, product steps, and downtime reasons. This standardizes your manufacturing process.

Capture machine metrics using various methods and store the data in InfluxDB Historian. You’ll have a comprehensive view of your manufacturing process to identify areas for improvement.

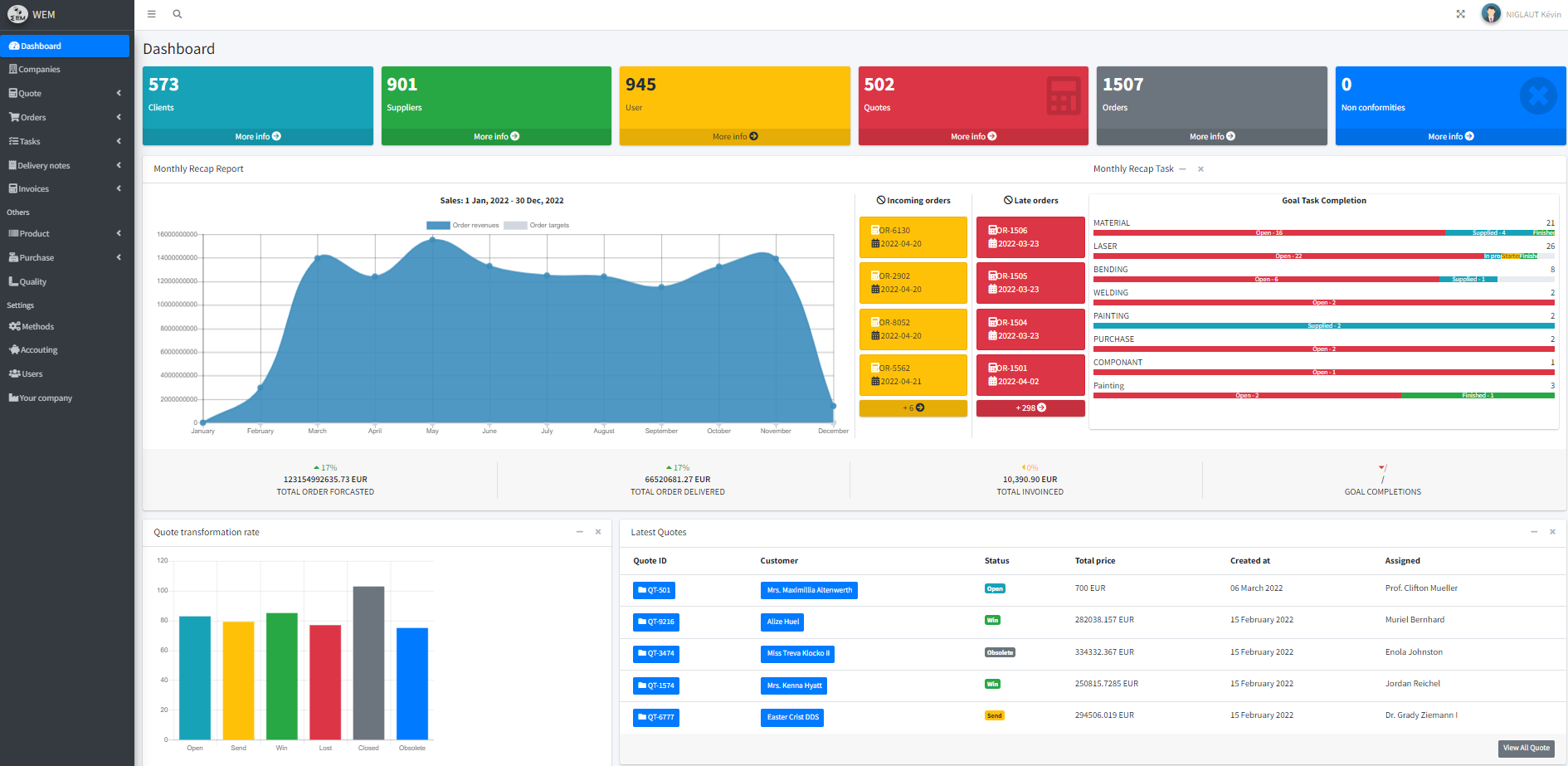

2- Web ERP and MES or ΣEM

Often, management systems offer full CRM and billing management. But if a link is missing between what is quoted and what must be manufactured. ΣEM offers a link between what the customer expects and a real-time status of the order in the manufacturing workshop. This project using PHP, Blade, Laravel 9, Livewire and bootstrap 4.6.

3- OpenPro

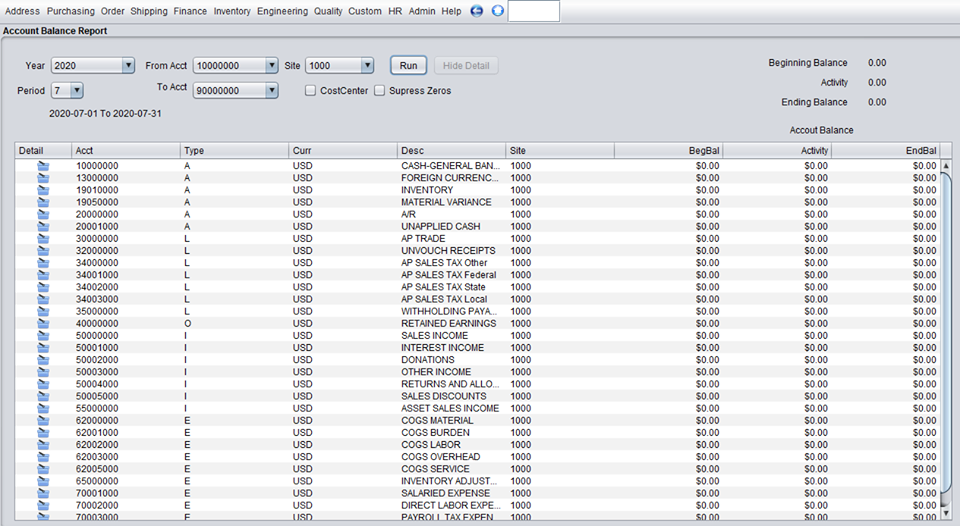

OpenPro’s open source ERP system provides accounting software for manufacturing companies of all sizes. OpenPro’s modular design provides manufacturers with the option to select the modules that meet their needs today, with the confidence that they can add new capabilities at any time. OpenPro modules include: Financials, Manufacturing, Distribution, Customer Relationship Management (CRM), and E-commerce.

4- BlueSeer ERP

'''BlueSeer ERP''' is a Free open source multilingual ERP software package. It was designed to meet the needs of the manufacturing community for an ERP system that is easily customizable and extendable while providing generic functionality that is typically observed in most manufacturing environments.

BlueSeer also provides a fully functional EDI mapping tool for EDI translations and file traffic monitoring. BlueSeer is released for free use under the MIT License. The application and source code are available for download at GitHub.com. BlueSeer was originally launched in 2017 and continues to evolve to meet user demands. The latest 'stable' release of version 6.5 was released on 2023-03-15.

BlueSeer ERP Features

BlueSeer provides modules for the following generic set of business concepts :

- Double Entry General Ledger

- Cost Accounting

- Accounts Receivable Processing and Aging

- Accounts Payable Processing and Aging

- PayRoll

- APIs for system to system integration

- Inventory Control

- Job Tracking

- Lot Traceability

- Order Management

- Service Order and Quoting Management

- Electronic Data Interchange (EDI)

- EDI Mapping tool (supports: X12, EDIFACT, CSV, FlatFile [IDOC, etc], XML, JSON )

- EDI Communications (FTP, AS2 server/client)

- Automated Task/Cron Scheduler

- UCC Label Generation

- Materials Resource Planning (MRP)

- Human Resources (HR)

5- IMES

IMES is an open source manufacturing execution system application designed for Small-Midsize JobShop Manufacturer.

A Manufacturing Execution System (MES) is a computer-based tool that monitors and records the entire manufacturing process, from raw material extraction to finished product production. These systems are stand-alone and gather data about the workplace. MES is applicable across various industries, including packaging, metal and plastic manufacturing, and automation. The primary goal of MES is to improve production efficiency, minimize delays, and streamline the delivery of goods.

An "Intelligent" MES builds on the original concept of MES by incorporating mathematical algorithms to aid decision-making. With an intelligent MES system, the information system can determine the most suitable solution for a given problem scenario. Manufacturers can improve their performance and reduce production costs further by using an intelligent MES system with enhanced decision-making capabilities.

6- metafresh

metasfresh is a responsive, Free and Open Source ERP System. Our aim is to create fast and easy-to-use enterprise software with an outstanding user experience. Equipped with wide and detailed functionality, metasfresh fits for companies from industry and trade that are searching business software that provides high scalability and flexibility.

It offers a highly customizable workflow for manufacturing, resources and materials management, user/ employee management and more.

It has a 3-tier architecture with Rest-API and a Web User Frontend developed in HTML5/ ReactJS/ Redux.

7- OpenXE

OpenXE is a comprehensive web-based application for handling all commercial processes.

Key Features

- Creation of offers

- Order processing

- invoicing

- Order management

- Warehouse management

- Customer communication

- Task and appointment management time billing

8- FrePPLe

FrePPLe is an easy-to-use and easy-to-implement open source advanced planning and scheduling tool for manufacturing companies.

When spreadsheets doesn't suffice any longer to adequately plan and schedule your production, frePPLe allows in an easy and cost-efficient way to generate a more optimized plan.

FrePPLe implements planning algoritms based on best practices such as theory of constraints (ie plan around the bottleneck), pull-based planning (ie start production as late as possible and directly triggered by demand) and lean manufacturing (ie avoid intermediate delays and inventory).

9- NotrinosERP

NotrinosERP is an open source, web-based enterprise management system that written in PHP and MySql. NotrinosERP contains all the required modules for running any small to medium size businesses. It includes full support for Sales, Purchasing, Warehousing, Manufacturing, Human Resource, and many more.

NotrinosEPR feautures highlight

- Purchase Orders

- Goods Receivable Notes

- Supplier Invoices/Credit Notes

- Payments

- Allocations

- Accounts Payable

- Items and Inventory

- Stock

- Manufacturing

- Fixed Asset

- Customizable Reports

- Sales Orders

- Customer Invoices/Credit Notes

- Deposits

- Allocations

- Accounts Receivable

- Dimensions

- General Ledger with Budget

- Languages

- Currencies

- Multi Currencies

- Payroll & Human Resource

10- Manufacturing Process Management (MPM)

MPM can be use to any manufacturing plant/units to maintain their stocks/data even at intermittent levels. Levels are processes involved to manufacture one unit/ item.

It required configurations such as level involved, units (weight,height) etc. as per business needs. Go through below points to setup, configure and understand working.