Can 3D Printing Really Solve PPE Shortage in COVID-19 Crisis? The Myth, and The Facts!

Table of Content

Amid COVID-19 crisis, we see severe shortage of Personal Protective Equipment (PPE) worldwide, to the point that a strict organization like FDA is making exceptions for PPE usage, and there are volunteer effors to try to alleviate this shortage like GetUsPPE. Also, Centers for Disease Control and Prevention (CDC) provides an Excel spreadsheet file to help calculate the PPE Burn Rate.

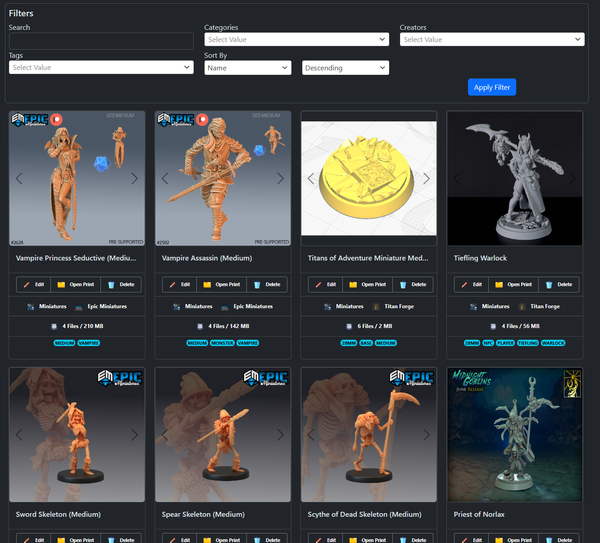

There are many blog posts, video tutorials, and guides that teach people how to print their face shields and masks.

Despite the fact of the 3D Printing community activities, hospitals and healthcare services didn't adopt it yet.

Some engineers and 3D Printing enthusiasts go beyond the proof-of-concept show-case to print and distribute 3D printed face shields and masks.

Here in this article, we will explore if 3d printing helps the PPE shortage? Furthermore, if it possible to overcome the known 3D printing limitations and can the 3D be printed products approved or regulated by healthcare authorities?

But first, lets shed some light on 3D printing for doctors and healthcare personals who are the primary readers of this blog.

What is 3D Printing?

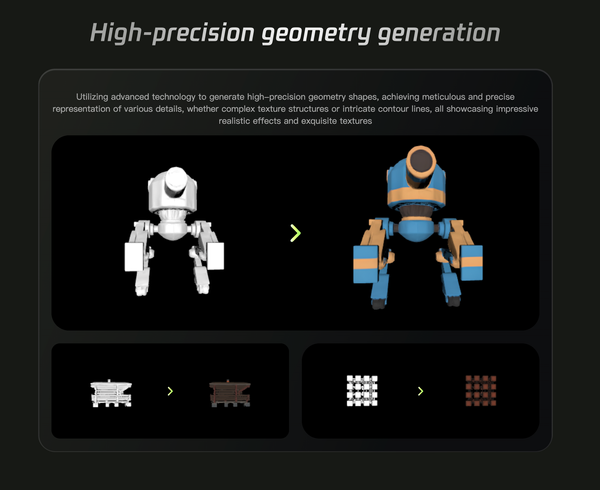

3D Printing (also called Additive Manufacturing) is the process of building three-dimensional objects from a CAD (Computer-aided Design) file.

Invented by Charles Hull in 1984, and patented in 1987. 3D Printing has the advantage of the speed, and it is significantly cheaper than the other conventional methods. It has many applications such as rapid prototyping, medical items, prosthetics, dental products, replicating artifacts, and even construction of buildings.

3D Printing in Medicine

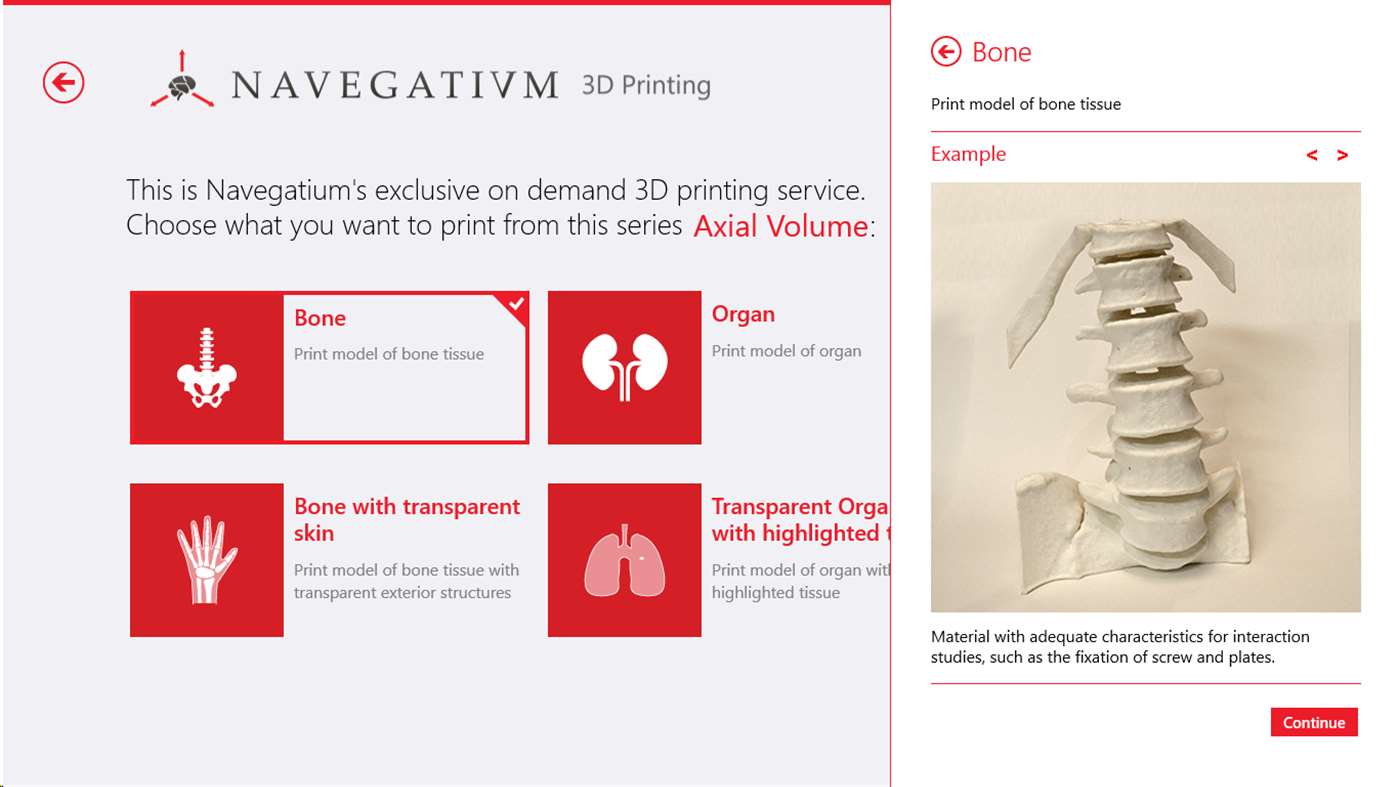

Medical uses of 3D Printing began in the 1990s in the form of dental implants and custom prosthetics, since then the usage expanded to more fields like bones, ears, hearing aids, blood vessels, tissues, organs, and more. 3D Printing is also used to print sterile surgical instruments and patient-specific organ replicas that surgeons can use to study, plan, and practice on them before doing difficult and complicated operations.

3D Printing is gaining a strong foothold in medical education, simulation, dental work.

Another innovative 3D Printing use-case in medicine is Navegatium; A Free 2D/3D DICOM Viewer with 3D Printing support for Windows.

How can 3D Printing help in the current COVID-19 crisis

3D Printing can be of great help amid the COVID-19 crisis. It can help alleviate the severe shortage of Personal Protective Equipments (PPE) in the market due to high demand. Some PPEs can be printed with 3D Printers, like what happened in the USA, UK, Italy, and many more countries.

3D Printing can be used successfully as a volume manufacturing technology. It is used to print COVID-19 test swabs, respirators, oxygen valves, face masks, face shields, and even 3d printed quarantine booths that have been made by a Chinese company.

What is personal protective equipment? (PPE)

Personal Protective Equipment (PPE) is special equipment and clothing that protect the user from health or safety hazards. The following is a list of medical PPE items:

- Surgical masks

- Respirators (N95 masks)

- Gloves

- Lab coats

- Face shields

- Goggles

- Gowns

- Shoe covers

- Boots

- Coveralls

Advantages of Printing PPEs

Printing PPEs with 3D-Printers has many advantages as saving time, costs, solve the problem of broken chain of supplies, and open the opportunity for volunteers who have 3D Printers to help the medical community.

3d Priniting has been called: a "citizen supply chain". However, the limitations of 3D printing are not to make mass 3D printing PPE products any easier.

The Myth

3D Printing can help fighting Covid-19

The Facts

Why can't 3D printing help in the Covid-19 crisis?

I don't believe 3D printing is ready at its current stage to support in Covid-19 crisis and here is why:

- It's not set for mass production, it's slow and costly

- Safety concerns, The 3D models are designed and released freely and not approved or accepted by national healthcare services.

- Sterilization concerns, 3D printing is easy, sterilizating the product is not.

- Can people carry on mass production or 3D printing their own masks and face shields in their basements? Making a mask is easy, On the other side, 3D printing thousands or even hundreds are not.

- Is it really cost-effective?

- It's not that easy to distribute 3D printed masks and face shields to doctors and nurses in hospitals without approval.

- The production should be regulated.

- If 3D printing is set to cover the demand, there is still steralization process, and fruthermore through inspection for all the products.

- 3D Printing is not for everyone, it requires skilled and knowledgable users

- Not every machine is for mass production. Researchers found out that the 3D Printing process releases harmful carcinogenic gases that lead to serious health issues. The recommended 3D printers are the ones with a HEPA filter that are expensive.

Conclusion

At the current stage, 3D Printing requires a lot of work, regulations, more organized work, needless to say, overcome the current common limitations for the technology. However, I believe this is expected to change in the near future as the COVID-19 crisis has put the 3D Printing industry in a real challenge.

Resources

- 3D Printing Limiations

- Coronavirus: Can we 3D-print our way out of the PPE shortage?

- Open Source 3D Printing for Medicine and Healthcare Examples and Use-cases