Logmore: Condition Loggers and Data Analytics for the Supply Chain

Products such as food items and pharmaceuticals often contain sensitive, perishable goods that need to be handled carefully during shipment and storage. If not handled with the proper care, these goods can go bad and have the possibility of becoming harmful for consumption. Businesses all around the world are losing money due to waste in the supply chain. In fact, 14% of the world’s food is lost through the supply chain.

One way to reduce such problems is to use technology-driven solutions to maintain visibility into conditions. Logmore provides businesses with a way to improve their supply chain management through the use of modern-day technology that helps capture and manage information pertaining to the status of shipments.

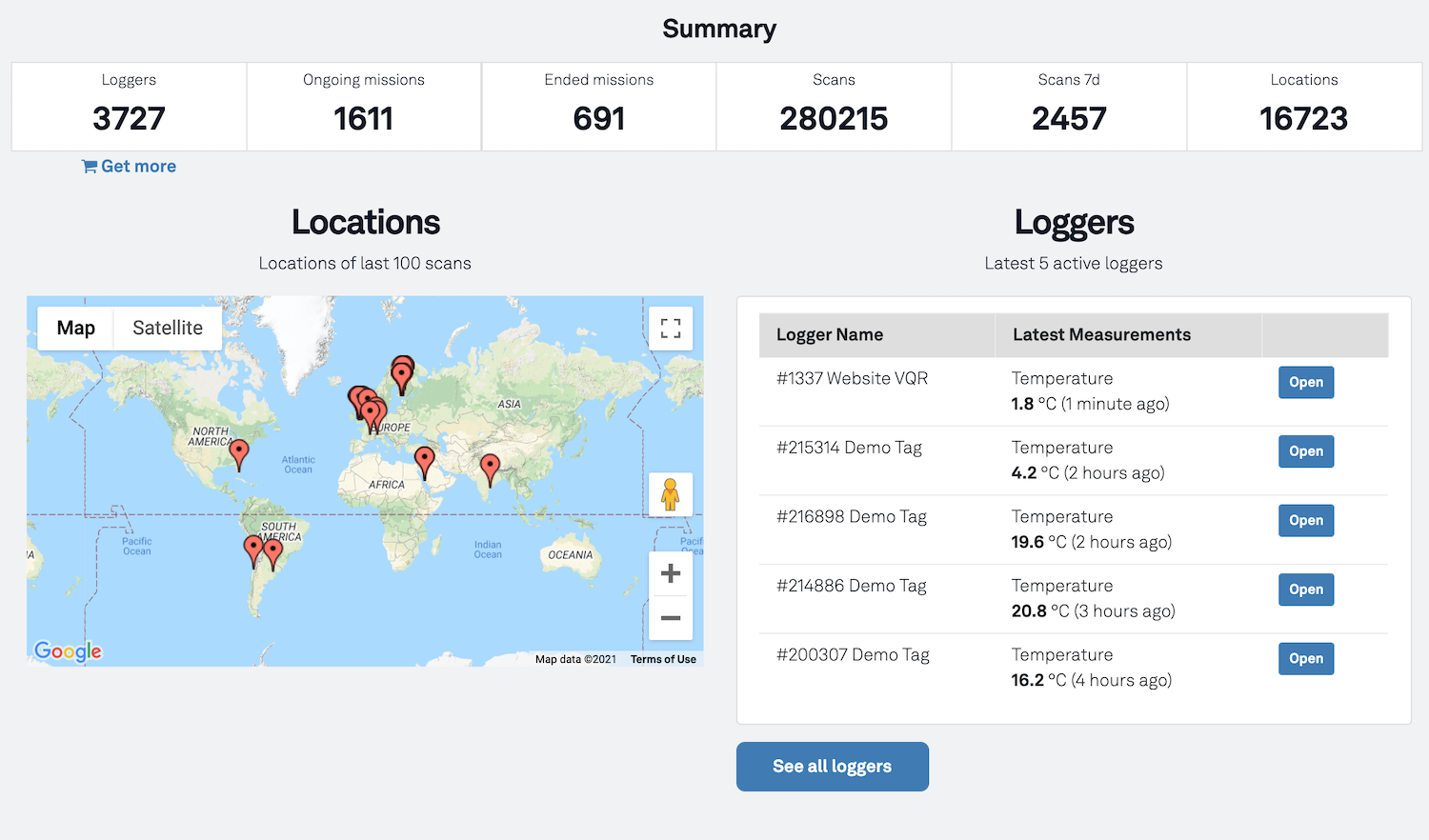

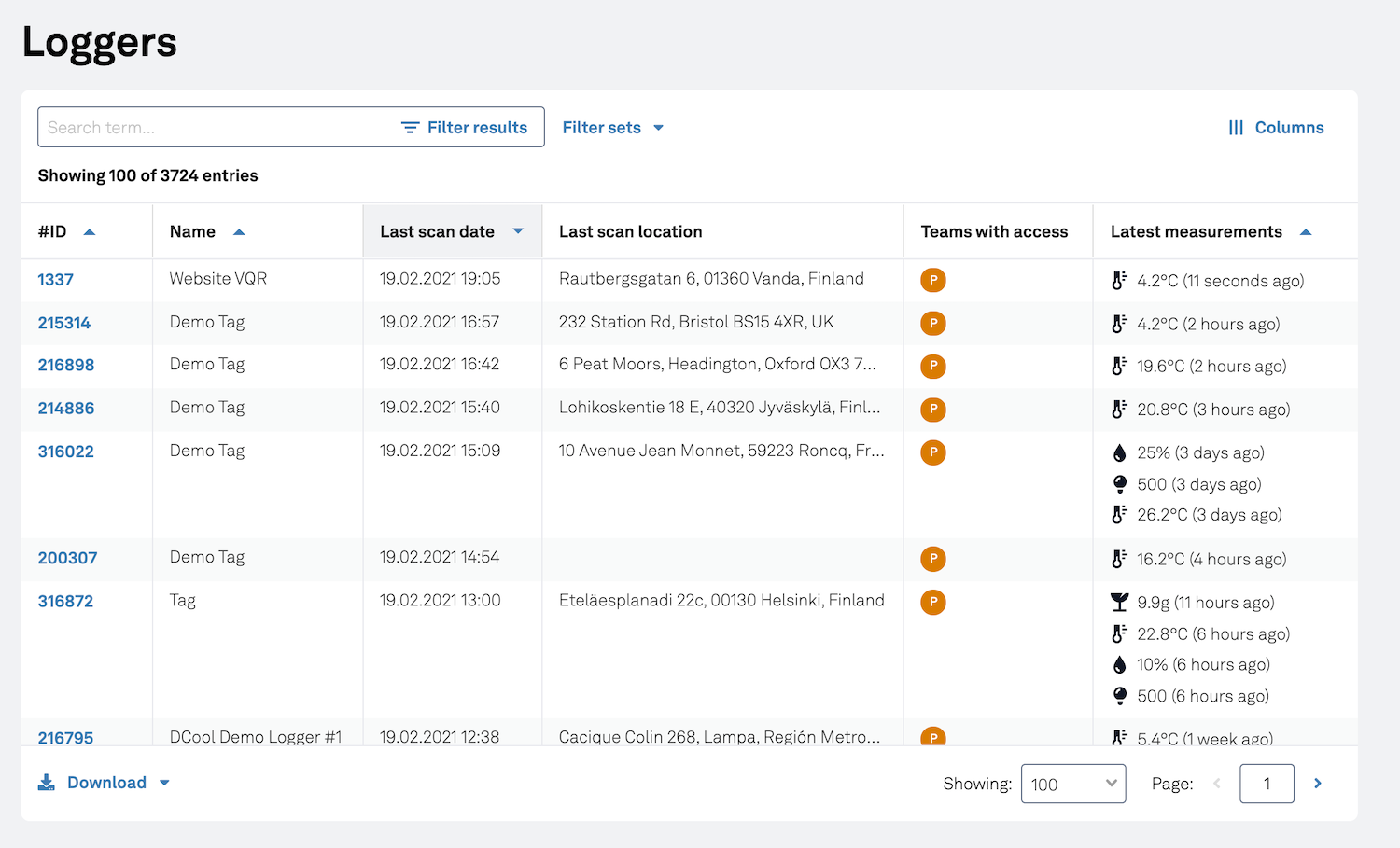

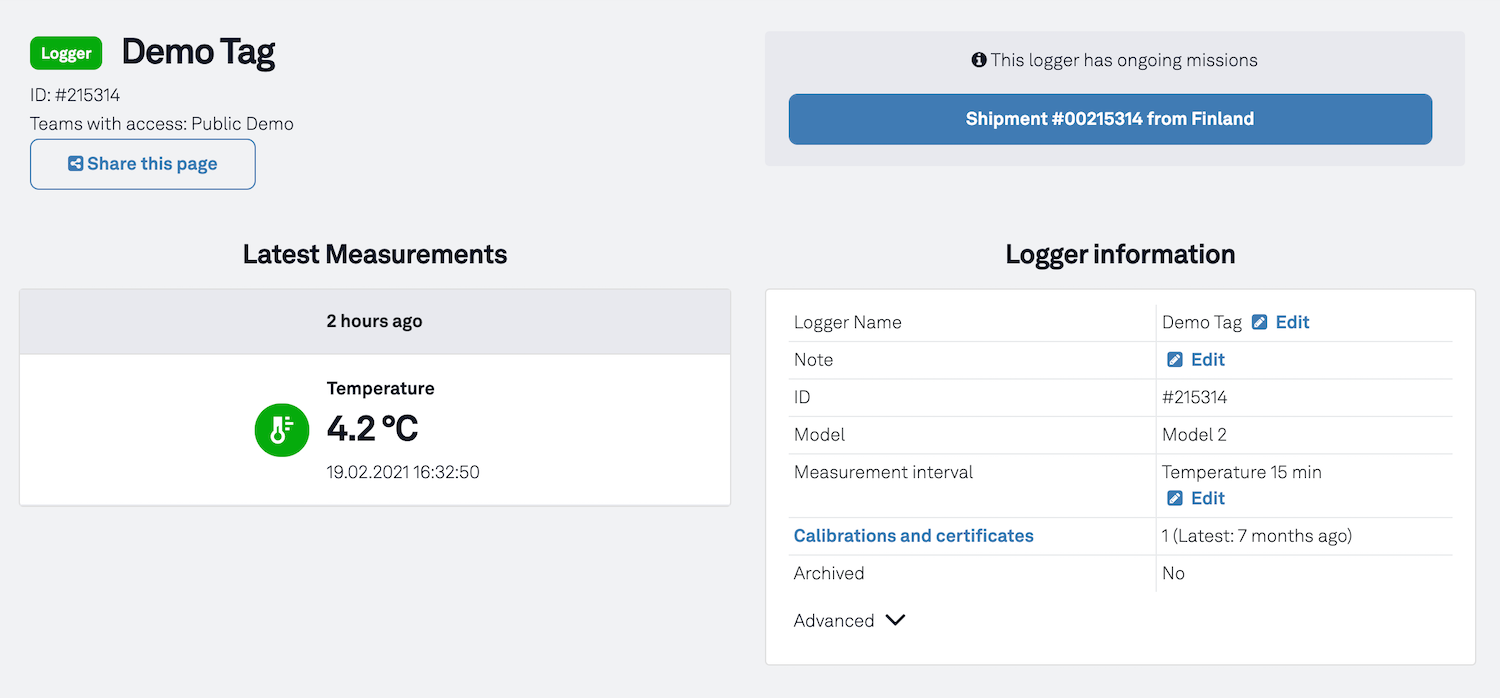

Logmore offers a data logging service for users to organize, store, analyze, and distribute data securely throughout the supply chain.

In this article, we’ll dig deeper into how Logmore helps companies improve their supply chain management and reduce waste in the supply chain.

Logmore: Overview

Logmore provides a shipment tracking solution for companies that need a more secure way of sending their orders to customers. Logmore’s tags sync with the cloud when people scan dynamic QR codes, which makes it even more lightweight and convenient to use for your products.

Compared to other solutions, Logmore’s data loggers are small and cheap to use on your shipments and can be attached to any sized package, making the QR solution a game-changer. There’s no proprietary infrastructure investment required, and no disruptions to data transmissions, as can take place with RFID or Bluetooth loggers.

Since Logmore’s tags help with sensitive and fragile shipments, businesses operating in the healthcare and pharmaceutical industries can really benefit from using Logmore.

With the help of condition monitoring, Logmore can help you transport vaccines and medicines that require special conditions to stay fresh and usable. You are able to get a better look at the status of your goods moving in the shipment process. Logmore can also reduce your supply chain losses through the use of intelligent sensors that can measure temperature, humidity, ambient light, and much more.

API Integration

Although Logmore is not open source, it does provide a very “open” platform for its users. Companies can integrate Logmore with other analytics platforms that they may use for their business management. You are also able to create your own custom apps for in-house use with Logmore’s API.

Data Accessibility

These days, companies demand more access to data and analytics as everyone – sellers and customers – want to know where their product is sourced from. This also increases transparency and promotes a good image for your company.

Logmore’s QR code technology can help you make your data accessible. With lower costs of supply chain monitoring, you are able to allocate more budget towards other aspects of your company.

Other than being a solid solution for reducing your supply chain monitoring costs, Logmore provides a reliable system as compared to using traditional RFID or USB tags.

The logistics industry can benefit from Logmore due to its features and benefits such as:

● Logmore’s QR codes are scannable even after being damaged. This makes them an especially attractive option for withstanding rough conditions of international freight. RFID tags tend to deteriorate after de-attaching themselves from your packages. You can’t just clean them and scan them like QR codes, which makes Logmore’s QR codes one of the best options for logistics companies.

● These data loggers are extremely resistant to temperatures, too. They are able to accurately measure conditions, helping companies get better control over the status of their shipments.

● Logmore’s data loggers can also be used to pinpoint where damages potentially occur which reduces legal protection disputes over damaged products and improves the quality of the overall logistics. By recording data at set intervals, Logmore’s data loggers help companies figure out where along the supply chain their package was damaged.

Reduced Supply Chain Waste

Knowing if your package is going to go bad before shipping can help you reduce your supply chain waste. This also helps ensure industries such as food and pharmaceutical can safely deliver their products all around the world without having to worry about the condition of their product.

QR data loggers can also make it easy for you to determine the cause of supply chain waste in your shipments. You can use the data you collect to solve shipping-related problems. Along with the convenience to monitor temperature, Logmore’s QR data loggers can help ship sensitive medicines and vaccines that require pre-defined temperatures to survive in transit.

Healthcare and pharmaceutical companies that use Logmore for their logistics place Logmore’s QR data logger inside their shipment boxes and don’t worry about anything else. For example, Magnum Medical Finland put Logmore’s QR data loggers in their shipments to monitor their shipments on a more detailed level, which helps ensure every package is usable for their clients.

Another great example can be found in the distribution of the Covid-19 vaccinations, which require especially cold temperatures. To help meet these requirements, the company has rolled out Logmore Dry Ice, an adaptation of the original data recorder systems, which is now being used in partnership with French shipping company Sofrigam to ensure safe delivery of the vaccine.

This allows shipments to be monitored even from your smartphone through the intelligent QR code system that displays and syncs data across your shipments. With better conditioning of sensitive shipments with Logmore, vaccination degradation can be reduced while transporting it all over the world.

Conclusion

With a better understanding of the possible failures in the supply chain system, you can reduce waste in your supply chain, ensure a better place for your company, and maximize profits. Logmore’s QR tags, analytics app and API make this all easier and more accessible.